|

Inscrutable

|

I am a 41-year-old professor of theology who is more at home with St. Thomas Aquinas’ arguments for God’s existence than the working end of a screwdriver. I have never sawed wood and never, at least to this point in my life, showed any interest in practicing the mechanical arts of any kind. Don’t misunderstand me. I have always admired good craftsmanship and those who produce beautiful and useful things. My lack of interest in these types of pursuits is not a form of intellectual snobbery. My interests and skills simply ran along other lines. And, truth be told, I am one of those people who some might consider to be “spatially challenged.” That is to say that it is very difficult for me to visualize things in 3D. On IQ tests, for example, I might be able to fold one of those boxes correctly 1 out of 100 times and this would be from pure blind luck. But even with this handicap, I decided to build Dave Carnell’s

$200 sailboat this summer. The thud you heard in the background was my wife of 21 years hitting the floor in a faint of stunned amazement. I guess even after 21 years of marriage one can still

surprise one’s spouse. The name of my boat – Inscrutable – originated here. Of course, I will make no further reference to the hubris women have when it comes to believing they know men all too well. Surprising my wife in this fashion was a gratifying coup and the satisfaction of it spurred me on in face of the frustrations that come with learning new skills.

|

Sail bent on for

first time. A final

inspection before loading up the truck

|

Inscrutable is constructed of ¼ inch marine grade fir ply, the frames are 1x3 stock, and the mast and spars are constructed from 2x4 stock. The shop where I bought the ply had milling services, so I had them cut the sides out for me for a modest $1 fee. This was probably the smoothest part of the building process. Things went down hill from here. When I joined the sides with an invisible butt strap the first time, the joint was so full of voids that it looked like a honeycomb. The two hours it took to sand down my mistake and prepare the sides for a new joining attempt was the closest thing to hell I experienced during the whole building process. Maybe it was just penance for my presumption that I could build this boat. The second attempt was successful and I was happy when it came time to join the bottom together that things went smoothly. Cutting the sides to dimension was little trouble, although I learned that one does not back up with a circular saw to rectify a mistake no matter how great the temptation is. Sand and File!

|

Inscrutable's chariot

|

Building the frames was the longest part of the process. It took me three times to get the frames measured and beveled correctly. I am a perfectionist and am not happy unless things are just right. The real trouble lay in trying to figure out how to slice a thin bevel (e.g., 9/64 in) into the frame with a table saw. Two 1x3’s clamped to the table saw guide did the trick. Did I mention that you need the steady hands of a surgeon? Where the frames took 3 tries, the transom consumed 4! On the last transom everything was perfect. The measurements, the fit, even the bevel. When I went to nail it to the sides, I found that I had beveled the transom in the wrong direction. My wife laughed, I cussed and headed to the basement workshop to build a face for it so I could turn it around and nail it in place!

|

Rigging the mainsheet

|

After gluing and nailing the sides to the frames, building went more quickly. My wife and a neighbor helped me cut out the chines, gunwales, mast and spars from a 16ft 2x12. In retrospect, I would use a rip guide on my circular saw for this part of the job. The rudder and leeboard were fashioned from ½ in marine grade fir plywood and the mast step and partner from ¼ in ply. Taping the chines and glassing the bottom went smoothly with the help of my wife. The tree under which we worked deposited some debris on our work. Some bugs were epoxied into the bottom. 1000 years from now some archeologist will find them perfectly preserved in their epoxy tomb although there will probably be no remains of a boat to suggest why they were preserved in this way.

I painted Inscrutable with exterior acrylic latex house paint. She is white with hunter green trim on the chines and gunwales. The mast and spars are also painted hunter green. I ordered a white sail to be made for Inscrutable and I expect that to arrive sometime this week. I am going to truck top the boat. I have a rusty ’81 Ford Pick-up truck and I built a wooden frame over the bed for this purpose. As I was fashioning this, one of my neighbors hollered and asked if I was “moving to Beverly?” It is certainly not pretty, but it will work. Another neighbor donated carpet scraps for the cross pieces that the boat will rest on.

|

The boat is amazingly stable.

Terry was surprised that there was

so little heel when she stepped aboard

|

It took me three weeks to finish Inscrutable. I have a little over 3 times the advertised cost of $200 in her. Some of this expense is due to the fact that at one point the learning curve was very steep and I had to pay for my mistakes. Some expense is due to the fact that I used bronze nails and fittings throughout instead of stainless steel and partly because I had a sail made for her when a used sunfish sail or a polytarp sail would have sufficed. I also had to acquire some tools even though I borrowed quite a few from my good neighbors. When I finished her I derived the same sense of satisfaction I feel when I have a professional paper published. The experienced boat builder will find many flaws in her – and I know these flaws intimately. What really amazes me is that all of my ignorance and fumbling and bumbling could not destroy the graceful lines of her design. For someone who had zero carpentry experience, she is beautiful.

Inscrutable clapped in iron! The

quartermaster pleads his case while blaming the cap'n

Instant boats, like the $200 sailboat, are marketed to those who have minimal carpentry experience. I am living proof that these boats can be built even if one has none. As far as I am concerned, Dave Carnell has the patience of a saint. He answered all of my questions with grace and dispatch and believe me, some of those questions were real doozies!

|

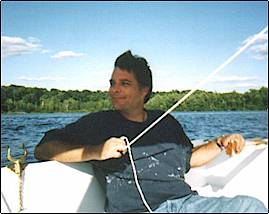

Inscrutable runs on a freshening breeze,

and I am one happy sailor

|

If there is anyone out there who has no carpentry experience and is wondering if they can build a boat, I would consider my own testimony as proof that you can. I would advise the rank amateur to take advantage of the designer’s desire to see his boat built well and ask

questions even if those questions seem simplistic or make you look foolish. What is obvious to the more experienced is not to the novice and having questions clarified before hand will save on mistakes. One example will suffice here: The boom of my sail is connected to the mast by a loop of line that allows for the boom to move without being blown so far away from the mast that it loses its ability to function. I assumed the loop went through the mast and the boom so I drilled a hole in the mast to accommodate the line. After drilling, I thought about the forces of wind working on the mast and figured I had just undermined the structural integrity of the mast to stand up to these forces. Do not drill first and ask questions later. If there is any doubt at all, seek the designer’s advice. It is gracious folks like Dave Carnell who can make your building experience a little less hairy. |

![]()