|

From the Boatshop

by Ron Magen

“Goolies & Ghosties

& Things that go Bump in the Night” . . .

Or so we chant at the young kids near the end of October. Then there is

Halyard Slap, Loose Docklines, Short Dinghy Painters, and a Dragging

Anchor.

Sometimes it’s simpler than that; something NEW, or DIFFERENT, or

OPPOSED to what the ‘experts’ say.

Recently a new restaurant opened locally. New in that location, and a

new ‘style’ for the area - Mongolian BBQ and Sushi. This is in addition to

one of the most extensive buffets I’ve ever seen, with an astounding array

of unusual, and changing, Oriental selections.

I’m sitting there, my plate filled with Kim Chee, Green Mussels, Rose

Shrimp, and a ‘pickled salad’ of whole baby octopus, squid, scallops, hot

pepper, & other seasonings. Joanne gives me a look, and says "What

IS that stuff !!??" When I tell her she responds with, "How can

you EAT that??. It’s worse than the raw clams & oysters you usually get."

"How do I know if I’ll like or not if I don’t taste it." {statement,

not question}

"Remember when I introduced you to REAL lobster on your first

trip to New England". {again, statement not question}. "Oh, it looks like

a BIG RED BUG !, is what you first said. Of course by the

end of the week YOU were showing complete strangers HOW to REALLY eat one

!!" Needless to say, she just kept forking in her ‘Shrimp and whatever’ .

. her usual, safe, choice.

It’s the same for boatbuilders & woodworkers ; "You can’t use THAT",

"You HAVE to do it THIS way", and ‘You NEED a

jointer for clean edges and really good glue joints". Of course we all

have our own ideas of a "Dream Shop" and I’m fairly sure Unlimited

space with Unlimited funds figures prominently in all of them.

However, reality is another thing entirely. While there are the ‘true’

Traditionalists who build lapstrake boats with strictly hand tools (as the

people at Williamsburg do for land based stuff) for the pure joy of the

‘Method’, for most of us it is usually a ‘means to an end’. It can be

recreational {"This is going to be the envy of everyone at the Marina"} or

a deadline {either Professional or Familial "Are you ever going to finish

that doghouse for Aunt Elaine ?"}. Also in line with the present reality

of precious few ‘off-time’ hours, almost all ‘non-professionals’ have &

use power tools. Many don’t realize that the purpose of a "Power Tool" is

not to do a better job, but to do the job faster.

By the same token, they don’t realize that the term ‘jointer’ started out

as a title for a person, then for a hand tool {a long-soled plane},

before it became synonymous with a type of power tool. Typically a large

and expensive power tool.

One of the habits you acquire as a small boat sailor, is making one

thing do multiple tasks. This tends to carry-over into other parts of our

lives. While I do have a Circular Saw, which is handy for ‘breaking down’

sheet goods and long stock to manageable size, for accuracy I use my Table

Saw. While it’s not the 500-pound ‘Cabinet Saw’ that the ‘experts’ call

for, I spent a lot of time deciding what was ‘right’ for ME. I’ve

previously written about my blade choices for it, and here is a

‘follow-up’.

Several months ago, in preparation for the ‘blade test’ article, I

visited a local saw sharpening service for an appraisal of the condition

of my ‘standard’ blade. When I told them what I was doing, they asked if I

would also test a RIP BLADE of their design & manufacturer. I told them

that I typically didn’t do a lot of rip work {a canoe builder WOULD do a

lot}, but would be HAPPY to accept their offer of a blade.

Because of the time interval, I’m sure they have felt I took the blade

and ignored them. I apologize to Dave & Matt but I felt it would only be a

fair test to use the blade in it’s designed application - GLUE-LINE

RIPPING of ‘solid’ stock. What I have been doing is looking for real

projects that required a lot of it. The two I have illustrated are the

Transoms of a ‘Cradle Boat’ and the building of several Mahogany ‘Flag

Cases’.

"NO JOINTER NECESSARY"

While the ‘Big Boys’ spend a lot of money advertising and

‘dueling it out’ in the national periodicals, there is a lot going on in

smaller shops. American Carbide Saw Company at 320 Springdale Avenue,

Hatboro, PA 19040, 215/ 672-1466, is one of them.

What I like about dealing with a smaller shop is the attention to

YOUR details. The typical rip blade has about 24 teeth . . . the

concept being the spacing & deep gullets carry away the ‘stringy bits’

since you are going with the grain of the wood. When I told them what my

normal work ‘mix’ was (and my ‘combo’ blade testing) they suggested I try

the blade they had developed; a 40 TOOTH with a 5 degree Alternate

Top Bevel grind and a 20 degree ‘hook’.

The ‘Experts’ criteria for a ‘Top Quality Blade’ seem to rest on the

amount of Carbide at each tooth and the accuracy & smoothness of the

attachment to the plate. THIS blade certainly meets those demands. While

it does a credible job on cross-cuts, and would be an economically

wasteful choice for ‘chopping up’ ply, it REALLY DOES do what it is

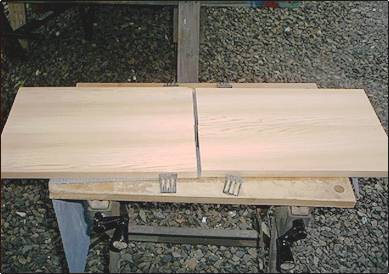

designed for. Look at the following photos of the Cradle Boat transom

blanks and finished. No jointing, no epoxy, no pegs or ‘biscuits’. Right

off the saw, a smearing of Titebond II, rub the surfaces together for a

few seconds, and clamp. Next day, scrape off the squeeze out and surface

sand. Since this was a ‘prototype’ [the ‘finished’ one is for a local

news personality] it got a bit of knocking around. Also a lot of

screws driven into it to hold springy sides and double bottom snugly in

place while glue dried. All in all a lot of pressure placed on the THREE

joints. Why three? Because one of the transoms is made with two boards

{one ‘joint’} and the other with three {two ‘joints’}. I can’t even tell

them apart.

for project update, mouseover

picture

My wife’s father passed away many years ago. When her mother passed

away a few years ago, one of the things she ‘inherited’ was the casket

flag. I thought about making a case for it but wasn’t sure if Joanne would

want one, but I quietly got a set of plans and put them aside. About a

month ago a family friend was visiting and mentioned that she was buying

such a case for her husband’s flag. Joanne immediately told her not to, I

could build it a lot better and for much less . . . I already had the

plans !!

Rather than buy dimensional Mahogany {MY preferred wood} to the specs,

I got the widest called out size, changed out the combo blade, and ripped

three sets of finished width parts. To give it a ‘real-life’ test I also

used it to cross-cut and angle-cut the pieces to length.

for project update, mouseover

picture

While I like this wood, it’s not the easiest on tools. Hard, with an

abrasive nature, it tends to dull a sharp edge rather quickly. A usual

indication of a dull edge it tearout of wood fibers. I did all the

ripping, then the 90 degree cross-cutting, then finally the 45 degree

angled cross-cuts.

The long rips had knife-sharp, 90 degree, corners. Smooth, straight,

and no burn marks. {Except where I ‘changed hands’ for a push stick

- - get or make a ‘non-slip’ pad type or ‘wide foot’ pusher. Also, move

long stock through faster, smoother, & continuously . . DON’T HESITATE}

My opinion ? While a benchtop jointer can be had for about $200.oo,

it’s not hefty enough or wide enough to make a decent surfacing unit. Nor

do they typically have a fence that can be adjusted to gibe you an angled

cut on the edge. A better bet would be to spend some of that money on one

of American Carbide Saw’s "GLUE-LINE" Carbide Rip Blades {ask for Matt

the foreman, or Dave the owner}. Use the rest for some Mahogany or

Walnut, or Ash stock and make something nice for the family.

And if you are in my neighborhood and like to eat, you’ve GOT to try:

OLD TOWN BUFFET

1495 Old York Road

Abington, PA 19001

215/ 885-0800

Ron Magen

Backyard Boatshop |