Evolution of a hobby – initial efforts

at boatbuilding

Or

Could this be becoming an obsession?

by Dave

Schau

Boat #1 –

beauty is in the eye of the beholder

After reading and surfing and ordering plans and more reading

and surfing and corresponding with some experienced boat builders

I finally decided it was time to try my hand at boatbuilding back

in the spring of 2002. I decided that a nice 12 foot Pirogue would

be a good project to start with.

I ordered several sets of plans

from different web sites. Some were much better than others. I

took design elements from many and started construction. I wanted

to eventually work my way up to stitch-and-glue construction,

but not right off the bat, so I decided to use screws, chine logs

and good old Gorilla Glue.

The first boat layout and construction

went okay, but as you can see from the results the boat had what

one polite and much more experienced builder called “interesting

lines”.

The hull came out quite angular

– I guess that would be good for angling? Well, maybe not…..

Here’s another shot of it

from another “angle”…

Okay, so it wasn’t all that

sleek, but the finish was very nice, it didn’t leak (or

sink) and the 14 year old boy I gave it to paddled around all

summer long on the pond on his farm. That alone was incentive

enough to keep going. I know I would have loved to have a boat

like this when I was a kid.

A few things I wanted to improve

on for the next project were:

-

Obviously those lines

– a nice smooth hull would be the goal

-

Slightly lighter weight

– Boat #1 had ¼ plywood sides and decks, 11/16

plywood flooring – total weight was probably 60 pounds

or more, a little heavier than I wanted

-

A more comfortable

seat!! That one is functional, but no padding – after

paddling for several hours one day I decided to go for something

more comfortable

-

Join the hull panels

with scarf joints, not butt them together with a rib like

this project

Boat #2 –

quite an improvement (thank goodness)

Keeping all the improvement goals in mind for the next project,

I pieced together enough ¼ plywood to make 12 foot hull

sides – using scarf joints. I wish I could find a picture

of them – they may have been the worlds ugliest scarf joints,

however they held together – somewhat (more on that later).

Did I mention that one half of each side of the hull panels was

Birch plywood and the other half Oak? I was using up whatever

wood was left in the shop (formerly a garage, but now a boat building

shop!!) The bottom was again made from 11/16 A/B plywood –

really nice stuff (used for soffets or something), but still a

bit too heavy.

Construction went smoother

this time. Have I mentioned how much I love sanding? The lines

of the boat were much more pleasing to the eye also. I made the

bottom a bit wider on this boat – 28 inches (boat #1 was

24) and it was much more stable on the water. It came out pretty

good I think – what do you think?

No ribs this time – but I

used spreaders to keep the hull flex to a minimum. These small

spreaders had to be replaced – too many people were trying

to pick the boat up by them, so I replaced them with nice solid

oak 1x2’s. (I should have got a picture of that)

So, boat #2 came out much better.

It paddled and tracked great. It’s a really nice boat. I

actually did some fishing from it also.

I made some of the improvements

I had hoped for:

However, it was still a bit heavier

than I had hoped for, and the scarf joints didn’t hold as

well as they should have. I ended up sanding (did I mention how

much I like sanding?) them down on the outside of the hull and

sealing them with epoxy and fiberglass tape, then fairing that

down with auto body filler. The hull came out nice and smooth

– nothing noticeable on the scarf joints at all.

I built this boat in the Fall of

2002 and kept it until Spring 2003 when I refinished it, cleaned

it up and actually sold it!! Yes – an actual sale on my

second project. Okay, so I sold it for less than it cost to build,

but it was for a very good cause, a Church rummage sale –

plus I needed the room in my shop to build the next project.

Boat #3 –

the $12 boat

I saw this boat on Duckworks and in the 2002 project listing $12

boat and decided this would be my next project. I was looking

for a boat I could use a trolling motor on (eBay winnings), tote

around in the back of my truck easily and fish from. After seeing

the article

on Duckworks I wrote to the builder and asked him in which month’s

issue did this article run – he wrote back: Popular Science,

March 1966 - and I was off to the library to get a copy of the

plans. Luckily they had the issue – and good old eBay once

again, I found the magazine and got it and a bunch more from 1966

for $8.

Construction was pretty simple

on this boat – not as much sanding either.

I put some additional features

into this boat:

Okay – it didn’t

work all that great, but it wasn’t bad either, I did end

up using a standard transom mount trolling motor on the boat however.

Overall, boat #3 was quite a success.

Easy to tote to and from the old fishing hole, very stable, zipped

right along with a trolling motor, and paddled quite well with

a kayak paddle also.

Some things to note about this

boat:

-

All ¼ inch

plywood construction

-

Gorilla Glue used

everywhere – that stuff works great – no leaks!!

-

This boat is definitely

NOT a 2 person boat in my opinion – one man one dog

is about all it will hold safely I think. I weigh about 165,

Lucky goes about 45 pounds, so I wouldn’t load too much

more into a boat of this design

(Does that life jacket make

me look fat?)

Boat #3 was given away to a good

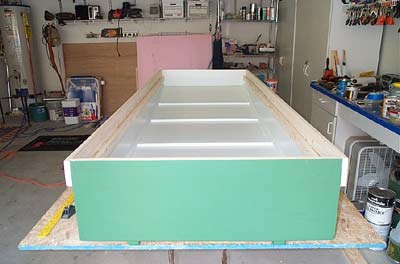

home, making room for boat #4, which is under construction now.

Another 12 foot Pirogue, made from all ¼ plywood and using

stitch-and-glue construction. The goal is to get the final weight

down less than 40 pounds and to get better overall results.

Results to be posted soon!!

|