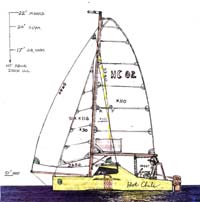

HOT

CHILI

15’ 3” CATAMARAN CAMP CRUISER

design by Jeff Gilbert

Jim

Townsend's project - Update1

- Update2

Update3 - Update4

- Update5 - Update6

- Update7 - Update8

Hot

Chili is a strong plywood asymmetric catamaran which can be built

by anyone who can measure, cut and glue timber, can be towed by

anything on four wheels, can be afforded by anyone with a job,

and can be used anywhere with a foot of water. Chili can be sailed,

powered, or both; and can be sculled over the stern. She can be

camped on at anchor by 2 adults or a small family, or beached

to set up a campsite. Minimal extra build effort renders her unsinkable,

in standard form she will float swamped. Last but not least, Hot

Chili is both striking and unique. Hot

Chili is a strong plywood asymmetric catamaran which can be built

by anyone who can measure, cut and glue timber, can be towed by

anything on four wheels, can be afforded by anyone with a job,

and can be used anywhere with a foot of water. Chili can be sailed,

powered, or both; and can be sculled over the stern. She can be

camped on at anchor by 2 adults or a small family, or beached

to set up a campsite. Minimal extra build effort renders her unsinkable,

in standard form she will float swamped. Last but not least, Hot

Chili is both striking and unique.

Jeff Gilbert Design #092

Imperial Specifications

| LOA |

16’-19’ |

| LOD |

15’ 03" |

| LWL |

15’ 03" |

| Mast ASL |

17’-28’ |

| Bmax |

8’ 2" |

| Hull Beam @WL |

1’ 4" |

| Draft |

0’ 6" |

| Deadrise |

0 deg ( ½ Dory hull) |

| Interior HRmax |

3’ (sit over hull berth) |

| Typical SA–Main |

100 |

| -Jib |

50 |

| Typical Working Disp |

800 lbs |

| Recommended Powering |

10 hp/ 17 knots |

| Aux Power (O/B) |

4 hp/ 10 knots |

| Inch immersion |

200 lb |

| Amateur Build time |

250 hrs |

| Batteries |

1 x 12v |

| Plan Cost |

$100 US* |

| Berths |

2 |

| SA/Disp |

(100%) 28 |

| Disp/WLL |

100 |

| Tankage/Galley/Head |

Portable Camping |

PLAN COST

The price will be 100 US dollars. Cost includes airmail. Australian

customers may wish to contact Jeff

Gilbert directly. You will receive a wad of drawings with

around 50 pages of text to help you understand and use them. Photographs

from the prototype build have been posted HERE.

I will put plan buyers in touch with all previous buyers who consent.

When sufficient numbers have developed I propose a Chili builders

web discussion group on Yahoo so myself & builders can help

each other along without repetition.

The price will be 100 US dollars. Cost includes airmail. Australian

customers may wish to contact Jeff

Gilbert directly. You will receive a wad of drawings with

around 50 pages of text to help you understand and use them. Photographs

from the prototype build have been posted HERE.

I will put plan buyers in touch with all previous buyers who consent.

When sufficient numbers have developed I propose a Chili builders

web discussion group on Yahoo so myself & builders can help

each other along without repetition.

CONSTRUCTION

Is fast, the boat being semi-monocoque, with a chine log but no

stringers. The protoype is one third complete after 60 hours.

Time savings are inherent in the design’s conforming to

the material – the flat hull and cabin outer sides are cut

from two joined sheets of 9mm ply. The sides are linked by an

8ft square 2-sheet 12mm bridgedeck, to form a flattened “H”section,

and thus define the entire outer shape. The bulkheads are placed

inside this, trueing up the structure and preparing for planking

the curved inner sides. The upper and outer edges of bulkheads

are lofted in sheet corners, exploiting the accuracy of factory-cut

right angles. After planking they form a tunnel, angling from

45degrees at the stern to vertical at the 6” x 1”

laminated stem. The stem protrudes vertically to take the front

cross-beam if it is required for nets and/or a spinnaker prodder.

Once the narrowish dory bottoms are on, the boat receives a layer

of glass below the waterline, the only glass used on the boat

except for some taping around the stem and other areas of end-grain

exposure.

TYPES OF CHILI

Essentially

you have an 8ft square level viewing platform which floats in

ankle deep water and is easily driven. From here the possibilities

for personalising Hot Chili are so vast that I expect no two to

be the same. However there are two major themes for Hot Chili…. Essentially

you have an 8ft square level viewing platform which floats in

ankle deep water and is easily driven. From here the possibilities

for personalising Hot Chili are so vast that I expect no two to

be the same. However there are two major themes for Hot Chili….

1. As a Sailboat with or without

small Auxiliary:

The cheapest way to go about this is to build the bare 15’

3” hull of Hot Chili (refered to as HC throughout these

notes) and transfer the entire sailing rig and rudders from

an old beach cat. In this way an older person like me can trade

in his or her beach cat for a more stable and only slightly

slower yacht on which one can go camping, and sail all year

round, getting wet only when one wants to.

Unless you are intending to use

a prodder (bowsprit) to run assymetric spinnakers, you can build

the simpler wooden front crossbeam, use a beam from your old

cat, or have no front beam at all, though this sacrifices the

chance of a net/tramp. The hardware should transfer directly

though you may need to lengthen your tiller arms, and will need

to calculate your daggerboard position to match the rig. If

you email a dimensioned sail and mast profile to jgilbert@webone.com.au

I will be happy to assist.

If you want an auxiliary motor,

use one you can carry easily, the smaller the better. If you

are buying new try to afford a four-stroke, they are kinder

on ears and fuel. The biggest I recommend is a 6HP, there are

now several (Suzuki, Nissan, Merc) long-shaft 4-strokes weighing

under 58lbs. A trolling motor would make a passable auxiliary

for limited use, position the battery bank as final trim and

you have power for a wonderful camping set-up. HC is an ideal

platform to experiment with bigger electric motors, outboard

or inboard, even in one hull. Imagine fishing a mountain lake

of a still evening, not a breath of wind and your campsite a

mile away. With an electric motor its an easy 12 minutes, barely

disturbing the scene.

The plans do not yet include

a tabernacle as they need to be tailored to the particular mast

and rig. I will add a generalised design for an unstayed mast

of around 20 feet.

Builders

experienced and keen enough to experiment with their own rig

designs will have a ball. Single sheet “Easy Rigs”

of the Rob Denney (see Duckworks design pages) persuasion are

perfect for this boat with the cabin peak to deck height offering

adequate bury. Tabernacles would also brace to the cabin roof

peak, and offer an opportunity to use the mast as a tent ridge

pole. I hope to find time to design HC a gaff rig for home building,

object being to complement the boats angular lines, whilst maximising

sail area on a low aspect rig. Some say this will be slow upwind,

I say if you are late for dinner start the motor. Builders

experienced and keen enough to experiment with their own rig

designs will have a ball. Single sheet “Easy Rigs”

of the Rob Denney (see Duckworks design pages) persuasion are

perfect for this boat with the cabin peak to deck height offering

adequate bury. Tabernacles would also brace to the cabin roof

peak, and offer an opportunity to use the mast as a tent ridge

pole. I hope to find time to design HC a gaff rig for home building,

object being to complement the boats angular lines, whilst maximising

sail area on a low aspect rig. Some say this will be slow upwind,

I say if you are late for dinner start the motor.

2. As a Motorboat.

With its an 18 inch underwing clearance higher than the few

comparable cats, HC will be quite at home in ocean, lake or

river. A 10HP motor provides close to 20 knots, so as a fishing

boat shes economical and swift enough to run for cover, and

beachable when she gets there. She can be winched up a beach,

or lifted bodily by 4 adults.

With her hull space available

for stowage, I see her best use as a weekend camper for two.

A standard tent can be adapted to fit her decks at anchor, she

can be beached to set up a campsite, and in extreme weather

one can retire to her dry bunks. She can carry 1200 lbs of people

and gear without complaint and only a couple of inches lower

in the water, but will performs better on her waterline, with

a third of this load. A 25 HP outboard will overpower HC unless

she is carefully trimmed for planing at over 25knots. I regard

15hp/20knots as a reasonable maximum, but would personally settle

for one of the many quiet and efficient 4-stroke long-shaft

9.9HP outboards available.

DESIGN BACKGROUND

Hot

Chili was drawn by hand in 1999, aiming to be the most attainable

2-person performance pocket yacht to date. By attainable I mean

it can be swiftly built in a garage with the spare time and funds

from an average wage-earners job. The term performance includes

both on the water (easily driven and handled) and off (strength

& longevity). Hot

Chili was drawn by hand in 1999, aiming to be the most attainable

2-person performance pocket yacht to date. By attainable I mean

it can be swiftly built in a garage with the spare time and funds

from an average wage-earners job. The term performance includes

both on the water (easily driven and handled) and off (strength

& longevity).

Speed and ease of build have been considered in every aspect the

design.

Many will claim that HC is sturdier

than strictly necessary & that it could be built lighter.

They are quite correct, and there would be some gains in launchability

& speed. There would also be big increases in both build time

and ability to capsize. What is the point in perusing those last

few ounces?? One can see at a glance this is not a racing boat,

it’s a fun camp-cruiser with a turn of speed. I’m

a big guy with big boots, & prefer boats strong. I’m

not a brilliant sailor, but love coastlines and sometimes sail

up rivers full of rocks, intermittently clouting them. Plus I

don’t like skittering 50metres sideways while I’m

fumbling with the daggerboard. You can tow the “heavy”

HC with 4 cylinders and the lightest of trailers, so build the

version that wont break if you make a mistake!

The abundance of right angles produced

by maximising use of factory cut ply sheets produced a tough-looking

design, yet one which calculated at less than one horsepower (HP)

for displacement hull–speed…Hot Chili could double

as a sheltered-water motorboat, or trailerable motorsailer. In

particular she looked useful as a river commuter, -at worst Hot

Chili would plane at six times sqrt(HP), so wouldn’t require

a big motor.

In 2002 I transferred the design

to computer to fine-tune and optimise the hulls for loadcarrying

& performance. The hull bottoms were broadened & inner

hull sides steepened from the original 45 degrees to facilitate

building, optimise Bridgedeck (Bdk) clearance, & make HC both

less tender and easier to lift onto a plane. This development

almost eliminated the original torturing around the bow –

the scarfed inner-side planking now just underwent a slight twist

along an easy curve. Flexiply was originally specified, its not

needed now.

These

developments don’t alter the extremely short build-time

possible in HCs simplest iteration – nothing in the hulls,

an 8 x 7 deck with a cuddy offering both dry stowage & a double

berth open to the stars, or coverable with the huge hatch in case

of rain or cold. No forebeam, simply an inverted “Y”

forestay to both bows, and swept back sidestays to chainplates

at the cabin sides just behind the windows. No spinnaker, simply

the single-sail cat rig from such as a Paper Tiger, or the main

and blade jib from something along the lines of a Hobie 14, giving

100 to 150 sq ft. These

developments don’t alter the extremely short build-time

possible in HCs simplest iteration – nothing in the hulls,

an 8 x 7 deck with a cuddy offering both dry stowage & a double

berth open to the stars, or coverable with the huge hatch in case

of rain or cold. No forebeam, simply an inverted “Y”

forestay to both bows, and swept back sidestays to chainplates

at the cabin sides just behind the windows. No spinnaker, simply

the single-sail cat rig from such as a Paper Tiger, or the main

and blade jib from something along the lines of a Hobie 14, giving

100 to 150 sq ft.

I sat on the design over 3 years

before finding a builder who would endure further simultaneous

development during the build! Thus these plans have the considerable

building and sailing experience of Jim Townsend seeded throughout.

Thank you, Jim.

Hot Chili offers beach catamaran

sailors the chance to stay dry and sail all year round, albiet

at a slightly reduced pace. Simply build your beach cat straight

over onto a Hot Chili hull, using everything, rig, rudders and

even the net out front and daggerboards if you wish. On a reasonable

wage one can afford both the time and money to do this over a

winter lay-up, losing no sailing time. If you don’t have

a beach cat, buy one cheaply in winter, if possible from a place

that’s cold in winter (sails less worn, boat cheaper). Its

good to buy from racing types who usually have lots of sails,

look after their gear, and are realistic about value. In Australia

you wouldn’t pay more than a thousand (550 US) dollars.

Huge possibilies open up for finding old garaged Pringles, Sol-Cats

and the like. You could be lucky and find a cheap one, say with

a damaged hull. Try your Yacht Club, Ebay, the newspaper. If you

don’t mind building rudders, you might go for a dinghy,

a Mirror or a Laser with its pop-in unstayed mast might suit.

Beware of ultra-high aspect rigs that are difficult to step, although

with a lighter person standing on the cabin you will be OK.

You can now have a dry boat you can camp overnight on, and can

take mates sailing all year round without handing them a dose

of hypothermia. You can also take Chili wherever you go behind

any 4 cylinder vehicle.

ALL UP COST

This depends on so many factors, not the least of which is your

enthusiasm which comes in finite and difficult to guage quantities,

and can run out before you cut a panel. For this reason you should

save time by using basic power tools, router, saw, sander &

drill. If you live in the Boondocks beg, borrow, steal, buy or

rent a small Generator.

If you are doing the most basic package referred to above, converting

a beach cat, double the cost of your ply and add the cost of your

beach cat.

There are about 16 sheets depending

on your lofting skills.

A full material list is being prepared.

OPTIONS

The plans provide for so many options that no two HC’s need

be alike.

The most complex Hot Chili would take twice the build time of

the simplest, yet may not be what you want. Look at the optional

items one by one and your Hot Chili will take shape.

-

Alloy Forebeam was conceived

to carry the Prodder for a Screecher (Assymetric Spinaker/Reacher)

This high performance sail was a requested addition.

-

The standard design plan

consists of building over a beach cat rig. If these have a

jib at all, it is likely to have an inverted “Y”

harness to fix the forestay to the bows (SS eyes thru stems),

and carry about 50sq ft of blade jib.

-

For “standard”

sail plans from a suitable (similar length) beach cat, one

only NEEDS a front cross beam to carry a net/trampoline. I’d

use the 3 x 2” timber beam sketched at the top of Drawing

5 , and sheath it in 6mm ply to hold a small upward curve

and help the bond to the stem stubs. I’d mount a tramp

to cut spray.

-

No front beam at all is

quite OK, especially for calm water use where spray is not

an issue. Many owners, especially of unrigged motoring Chilis,

will never venture forrd of the cockpit.

-

Hull Berths, two at 80 x

21”.

-

Rear seat (increasing Berth

convenience)

-

Footwells, mostly used sitting

on the rear beam which can be up to 14” wide over the

hulls.

-

Motor/sculling oar.

-

Fold-up side decks.

-

Rear steps

My choice would be a wooden front beam, no prodder and

an assymetric cockpit. This means a seat one side with the attendant

larger hull berth having the larger permanent access opening

which would be covered by the hatch when in motion. A single

footwell in the diagonally opposite corner would complete the

“high seat/low seat” cockpit. The secondary hull

berth would have a flush-fitting hinged lid where the outboard

could be locked to secure the yacht.

DIMENSIONS

The

boat is designed imperial for Australian and American ply in

8 by 4 ft sheets. I’m not going to convert plan dimensions

to metric and here’s why. If I do, someone will go goody,

rush out and buy 2400 x 1200 ply, and start building in metric

with these undersized sheets. If one converts the dimensions

directly by the usual 1foot equals 304.8mm then starts building

with 2400 x 1200 its only a matter of time before you get into

an insurmountable mess. At best the last things you create will

be cumulatively undersize, at worst things wont fit at all. The

boat is designed imperial for Australian and American ply in

8 by 4 ft sheets. I’m not going to convert plan dimensions

to metric and here’s why. If I do, someone will go goody,

rush out and buy 2400 x 1200 ply, and start building in metric

with these undersized sheets. If one converts the dimensions

directly by the usual 1foot equals 304.8mm then starts building

with 2400 x 1200 its only a matter of time before you get into

an insurmountable mess. At best the last things you create will

be cumulatively undersize, at worst things wont fit at all.

Solution If you

can only get 2400 x 1200 ply, build in mm and scale down the

whole boat as you convert the imperial dimensions. This is as

easy as falling off a log. The design requires 8-foot sheets,

you have 2400mm sheets. Convert the plans at 1 foot = 300mm

and 1 inch = 25mm. Voila. (Your boat is 1.6 percent smaller

than the design, bad luck, you live in a country that makes

undersize ply!!!).

GET WOOD !

Start stockpiling timber now! Grab odd bits of scrap ply

and pine offcuts, there are skips fiull at building sites headed

for the dump. Grab bits of oregon and hardwood,, you only need

a 2ft 6 ins of 6 x 1 for your stem. Youll need an assortment

of sizes for bracing, temporary struts, measuring (a stick and

a pencil dont transpose figures) and padding clamps (collect

clamps too). If you don’t have a ute, put it in your boot,

tie it on the roofrack. Boatbuilders cars should be sacrificial

items.

The main structure of Hot Chili depends

on the manufactured ply being true, try to buy it all together

from the same firm or preferably run, so its all the same. If

you want a boat with incipient cancer, buy the cheapest ply.

Use the best you can find, at least BS1088 Boat Building Standard

ply. This might seem expensive, if check out Duflex panels or

foam core FG and see the price of getting covered in toxic crap.

(They will tell you its easy, fast and fun, but you wont care

what they say, because you will already be too frightened by

the price). Go back and buy the marine ply. You still need a

bucket of epoxy and 10sq m of 290g/sq m glass cloth, but only

a tenth fraction of foam core or full FG layup.

Even

if its further and dearer, a lumberyard which knows boats will

save many tears, and you’ll feel confident about your

purchases. If you are in a multipurpose hyperbarn with a zillion

grinning idiots with uniforms and nametags, buy some cheap sandpaper

and leave. You are looking for a yard where they consider your

project, have the time and knowledge to tell you what you are

getting, and will help selecting your own straight grained lumber

and knot free ply. This last is probably superfluous, marine

standard ply has at least one good face, waterproof glue in

the right amounts and no hollows. Even

if its further and dearer, a lumberyard which knows boats will

save many tears, and you’ll feel confident about your

purchases. If you are in a multipurpose hyperbarn with a zillion

grinning idiots with uniforms and nametags, buy some cheap sandpaper

and leave. You are looking for a yard where they consider your

project, have the time and knowledge to tell you what you are

getting, and will help selecting your own straight grained lumber

and knot free ply. This last is probably superfluous, marine

standard ply has at least one good face, waterproof glue in

the right amounts and no hollows.

DESIGN DECISIONS

-

Speed and economy of build

are the prime objectives of the boat, and take precedence

over looks, comfort and performance in most decisions. Nevertheless

the boat won’t obviously suffer in any of these secondary

areas. All but a few design dilemmas were solved by answering

the question:- “Which option is the easiest to build?”

-

An exception to #1 above

is the 1.5” bend towards the centreline of the cabin

top, making the inside width of the roof 7.75feet to the bridgedecks

eight. This is done to prevent leakage & possible delamination

at the top of the cabin sides (the cabin roof can now cross

this exposed end-grain) , to aesthetically relieve the constant

right angles, to make it easier to work the daggerboards without

grazing knuckles, and to provide more width for crew on the

optional hinged fold-down side-decks.

-

Side-decks may either complement

or replace the hinged roof as a means of forrd access. They

should hang from light (possibly plastic) chains & hooks

(thus making their angle adjustable) and sit at a slight up

angle of about 80deg to the cabin side, ie 100deg to the hull.

At this angle they will make effective buffers. A long notch

or slot in the side-deck edge where it hinges to the boat

side replaces the upper positioning rung of the daggerboard

, implying that the corresponding side-deck must be down for

a board to be used. Side decks should be just wide enough

for crew to “sit out’ and balance the boat on

a fast reach. They can be used for a spot of mild hiking –you’ll

need to build some timber hand-rails along the cabin-tops

at a comfortable distance between the edge and hatch.

-

Despite absorbing a foot

of accommodation length, the integration of the Bdk with both

crossbeams is literally a design strongpoint. Additionally,

there is far less work in setting up and building the beams,

they are ideally spaced at half boat length, and there remains

enough space (83.5” x 48”) for a couple to sleep

longitudinally. Some crew find the motion of multihulls makes

sleeping athwartships uncomfortable. The answer is to beach

the boat, it’s designed for it.

-

Beaching Protection:

The last action before painting the upturned boat is to add

some sacrificial 1 x ½” hardwood laths to the

bottom and optional rear fin. These could be capped with metal

channel or stripping, held on by a bedding material such as

Sikaflex.

GENERAL

Purbond

waterproof glue is perectly adequate for build joins, and less

messy than epoxy which can be reserved for filletting and filling.

Save your fine sawdust, or wood flour as it is sometimes called

by boatbuilders with aspirations to Chefdom. This is great for

thickening epoxy for filling and filleting (more cooking imagery). Purbond

waterproof glue is perectly adequate for build joins, and less

messy than epoxy which can be reserved for filletting and filling.

Save your fine sawdust, or wood flour as it is sometimes called

by boatbuilders with aspirations to Chefdom. This is great for

thickening epoxy for filling and filleting (more cooking imagery).

Don’t epoxy anything except joins,

and areas that are about to become inaccessable, until the boat

is complete, or you’ll exhaust yourself and blunten your

tools working with material which you’ve just converted

to virtual steel. An argument rageth on the web, time penalties

for this approach are being debated at 7 times.

Without FibreGlass Hot Chili wont necessarily

leak. To be certain fiberglass the bottom below the waterline,

and better still from outside WL to outside WL right across

the bottom of the bridgedeck, which is only 10 square meters

maximum. One layer of 290grams/sq m. will do, we want a water

barrier not structural strength of which we have plenty.

Any start-points for delamination should be covered with FG

tape other key areas such as the stem, around transoms and anywhere

that a ply edge is exposed –these are lethal. Several

coats of epoxy on such edges is likely to prevent delamination,

glass taping will.

ACCOMODATION & USE

HC accomodations were designed at Bridgedeck level for simplicity

and flexibility. There is plenty of hull stowage, and the 41½”

x 23” flat hatch cover stows upside down under one side

deck. This has no impact at all on the resultant enlarged day-sailing

deck which also provides access to the mast. Moving forrd is

rarely necessary, but good for cooling off on the net/tramp.

It’s simply a matter of stepping over the windscreen,

or sitting on the roof peak and swinging your legs over.

Though it makes the build more complex, those

who wish may incorporate hull berths between BH1 and BH4. These

have myriad advantages, not the least of which is one can get

up in the night without disturbing the other. Hull shape &

size dictates feet-forrd, & theres not much room under the

crossbeam. Entry is tight, but easy with the hatch off, simply

swinging under from a grip on the hatch coaming. Once installed,

you will be really comfy, and well supported in a seaway. All

but the biggest sailors can fit the berth low enough in the

hull to provide sitting headroom, even with HC’s low cuddy.

Hull berths would be a real boon to serious coastal cruisers,

who wished to eat up some overnight miles with helm watches

interspersed by ballast duty in the windward berth! The shakedown

cruise for Hot Chili is to be a 400 mile reach on the Australian

coast, returning by road. Hot Chili will lap it up!

The large stowable roof hatch essentially

removes all but the windscreen and strength-providing roof peak

across the boat. This setup lends itself to mosquito netting

& a various standard tents. A standard 8’x 6’

A-frame would fit around the coaming/cabin edges. A poleless

igloo 8 x 8 would go over cabin and all, secured around the

sidedecks and XBeams. If the boom were lashed out of the way

or hoisted, one could attach the peak of such a tent to the

halyard.

With a calm sea and 10 HP, Hot Chili will

happily bowl along on half throttle at 12 knots, and hit at

least 17 flat out. Builders with motoring in mind may wish to

raise the cuddy design against spray, and either eliminate the

rig, or rationalise it by removing the prodder and installing

a mast tabernacle. To optimise this dual role, the designer

is researching a source of telescoping 20ft alloy masts.

Hot Chili is a real solution for those who

think they are doomed to save forever for “a decent boat.”

You can savour the feeling of sailing a boat you built yourself,

and you wont be exhausted or broke by launch day. You will sail

past boats costing 50 times as much, and can take your boat

on holiday without making the drive a nightmare. You can spend

200 hours building and 2000 sailing, instead of vice versa.

Your boat will be the focal point at Messabouts and Wooden Boat

Festivals. Hot Chili is enviromnmentally sound. Hot Chili is

heaps of fun. Can you think of a better way to go?

Yours Faithfully

Jeff Gilbert 2003.

|