RIDGID’s Big Bargain Table Saw Review

Well I have been holding back and using this saw for months before I decided it was time to write my review. Techtronics Technlongy Inc., that owns the Ryobi tool brand now owns Ridgid and just bought out Milwaukee tools also. This is the first big saw of the new Ridgid company and I really didn’t know what to expect. Ridgid is a professional brand of tool as compared to Ryobi or even Milwaukee. Just as in the Planer test I first did and the other tool tests I had to have something to compare this tool with. I have a Ryobi 3100 table saw an old Delta table saw, both 10” saws I might add and now I have been testing this great Ridgid table saw.

I had read some unfavorable complaint about this saw on a few tool forums b people who looked at them in the Home Depot tool departments. One complaint was that the legs wobbled like a Hula dancer and the other was that it didn’t have a zero clearance throat plate for the best possible cuts without tear out. Both of those allegations were disproved but I am getting ahead of myself.

I picked the saw up off the rack a my local Home Depot store, well not me but two very big guys because this thing is heavy. With the help of my wife and neighbor and a furniture dolly we got both boxes for this saw into my shop. The table and wings of this saw are cast iron. Solid and very heavy cast iron so when you buy this saw be prepared. My Ryobi saw was a snap to assemble compared to the Ridgid saw because it is made of light weight aluminum. When you want very accurate work you want a saw that does not move and to be sure the Ridgid saw will not move when I is not picked up n it’s built on wheels to move it around the shop. It is also almost theft proof because one person can’t pick it up without hearing their hernia snap like a large rubber band! In fact two men would be hard pressed to move it without the built in wheels, with them a child can glide the machine around the shop without much force.

Again I’m getting ahead of myself because they have a very thick building manual for putting the saw together and setting it up to function properly. RTFB, that means “read the frigging book“! I think the reports I read about hula legs and other things were from miss assembled saws at the Home Depot stores. This saw will take about a good long day or about three work nights to put together. Since I can’t lift to much weight it took me about a week and trying to get new volunteers each day got harder and harder. If I was thirty again it would have been a snap but I can only do a little work at one time and then I have to rest and go back later. It did give me plenty of time to take notes and RTFB. Back at the other forums where the Hula legs began I can only imagine a new minimum wage employee throwing away the readable manual and assembling the table their own way. It is a common thing done to Ryobi tools and in most Home Depot stors you can see the Ryobi section in complete disarray.

The first thing you will notice is that the belt that drive the blade arbor is like the new style fan belts on cars. Instead of using two vee belts they use a wider serrated belt that works much better than the two belt system. I measured the end play of the Arbor before and after running the saw and it remained zero through out all the testing. It uses sealed self lubricated bearings that should be good for years although grease fittings would be nice on some of the newer machines instead they are all sealed for life. This gives the user no way to make sue his saw will last for years, sort of a built in obsolescence. The arbor is held with very heavy cat iron castings and pivots very nicely. The Controls for blade hieght and angle are separate and that is a good thing unlike the BT 3100 Ryobi that has them built into one control. Thee controls use actual metal handles and work very smoothly.

Lats face the fact that even though the parent company that now owns Ridgid owns Ryobi also, these are two entirely different saws. The Ryobi saw is great for a part time wood worker and comes with hundreds of attachments that make it more versatile than almost any saw mad but it is all Aluminum and just isnot a stable as saw made from cast iron. The motor on the Ryobi saw runs at very high RPM’s and does bog down in long cuts of hardwoods. The Ridgid saw is built super strong for the long run. It is not easy to move while working on it and that makes it more accurate when you are cutting hard woods to very fine measurements. The motor is sealed and cooled and also can be used in 220 power. This lower the amperage needed to turn the motor and lower amperage means lower heat. Lower heat means the saw will last longer, it also means that it cuts with a Dado blade without heating excessively.

Now we get to the table saw legs, the ones that were commented on being so suspect in some of the forums I read. They are pressed into a round curve from very wide 90 degrees at the top into a long taper to the bottom. Everyone knows that curved surfaces are stronger than plain flat surfaces. Then the legs are bolted to the bottom of the heavy sheet metal box of the saw. They are also braced with four metal bars in such a way that allows no movement in any direction. If all the bolts were to be only fitted with enlightened bolts the legs would be able to move. This is what I think happened when people reported on the movment of th saw and unstable legs. Then you add the Her-Cu-Lift, a device that lowers a set of large roller bearing wheels down to allow movement across your shop floor easily. With all of those brackets mounted to the whole leg system of the saw it makes the legs even more stable. Even when I put my full weight sitting on top of the saw table (do not do this at home) my helper was not able to make the legs wobble or move. I did use locktite on all the bolted assemblies to make absolutely sure that through use the saw would not loosen any leg bolts or any bolts that I used in assembling the entire saw. I highly recommend this in assembling any power tools in your shop. I still do preventive maintenance through out the year to make sure all bolts are tight and belts are correctly tensioned and to look for any safety problems such as cracks or chipped carbide from blades. With heavyuse like making long cuts for building lager wood projects it is a good idea to unplug your saw every morning or when ever you start and make sure everything looks good before plugging back into your power source. I always grab the blade of the saw and check for any side play and turn the blade slowly to check for any run out or broken carbide teeth on the blade. Nothing runs a cut faster than a loose blade of cracked or chipped carbide cutters.

All it takes is one small staple or brad nail to ruin a quality blade. If you catch the problem quickly enough the expensive blade can be repaired usually by the manufacturer. Another problem I see in about 70% of all the shops I look at is the problem of dull blades being used to literally burn their way through wood leaving black cuts. Saw blades can be sharpened in most areas by qualified mill writes that have drop off places at most big lumber yards and they charge very small amounts compared to buying new blades and they will true up your blade so it may even cut better than it came from the factory.

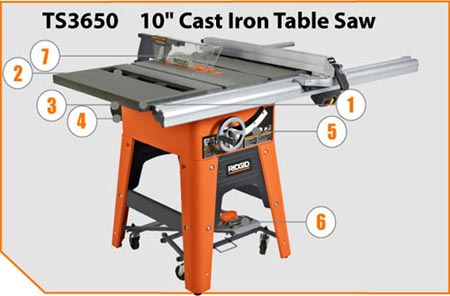

| |

Feature |

Function |

Benefit |

| 1 |

Solid Cast Iron Table/Extension |

Provides solid, stable support surface for the workpiece |

Greater support, less vibration |

| 2 |

Clamping Ledge in Tabletop |

Allows for jigs and featherboards to easily be clamped to

the tabletop |

Faster set-up, more versatility |

| 3 |

TEFC Motor |

Totally Enclosed Fan Cooled motor design protects from

debris |

Longer motor life |

| 4 |

Dual-Voltage Motor |

Powerful induction motor can be used with 110v or 220v |

More versatility |

| 5 |

Cab-Forward Design |

Front of the cabinet is moved forward closer to the user |

Easier to read scale, reach handle |

| 6 |

Includes Herc-U-Lift™ casters |

Allows for easy movement of the saw by 1 person |

More versatility |

| 7 |

Quick-Change Blade Guard |

Guard can be replaced/removed with no tools |

Greater convenience |

| 8 |

"T-Slot" Miter Gauge and Slots |

Provides additional accuracy for crosscutting |

More precise cuts |

The universal blade that comes with the saw is of fine quality and if your doing cross cuts and ripping in your building process then you can leave the blade on the saw but lets say you have a whole pile of cedar that you need to make strips from to build a stripped planked boat then by all means use a ripping blade fit to the saw. The same way if you are doing nothing but cross cutting then mount a good extra fine cross cut blade. It make a huge difference in the quality of the cuts you make by using the correct blades for the job.

Ridgid also makes zero clearance plates for the TS 3650 Table Saw so split out and rough edges can be stopped. Now sadly there are rumors that these items are not available for these saws but I can put that false rumor to rest. Not only are they available for single blade operations they are also made to use with dado blades also. I was very pleased with the saws ability to use separate knobs for cutting angle and height as most higher end saws separate these controls. If the hear of a table saw is the motor and arbor assembly then the Fence and rails are the fingers that allow it to be accurate. I have used a high end after market fence for this Ridgid saw just to see how well it would work but believe me the standard fence system is very nice with great accuracy. It has slots for add on sacrificial wood or different jigs that can turn your saw into a cabinet saw or any other types of cuts you need to make for this saw.

In Fact the fence is one of the top features I found I liked about the saw and it also has a magnifying glass over the inch scale so even poor old blind farts like myself can see the size of cut I would like to make. With the large rails that come with the saw as well as the different accessories you can bu for it like the zero clearance throat plates the saw is a winner in my book. I used several after market brand blades that I had in my shop from using my other 10” table saws and they all worked very well with this great saw. I even used the Freud dial adjustable dado blade with this saw with good effects. When you look at this type of saw from the top four saw producers you can tell that they all have about the same features but like all things some are better made than others. In this contractors saw selection Ridgid has provided a tough well built saw with good simple and strong components. The same type saw from Grizzly has a much poorer designed fence and rails. The only other competitor might be Delta but Ridgid gives you the same quality for less money making this saw a real bargain. I think it is a fantastic saw and bolt on accessories from many manufacturers fit perfectly on it. In fact one of them is in this spring extravaganza article the Penn State Ind. Table Saw Over Arm Dust Collection System. With the use of any zero clearance blade insert at least 70% of the saw dust is now kicked to the top of the saw table With this add on and I recommend this one for this type of saw so you get more clearance Your table saw stays virtually dust free and it sure makes it easy to view your cut line even right next to the blade while cutting. I use a big Shop-Vac system in my small shop and it is more than adequate for the table saw but when my big shop is done I will be switching some tools over to my big Dust Cyclone system also from Penn State.

I can recommend this saw because it has al the features of saws costing more and one more big feature that other saws do not come with and that is the Her-Cu-Lift saw mover that lets you roll the saw around the shop buy a small child. On other saws this is more than a hundred dollar option making this saw the absolute best saw for the price. Easy portability on a smooth floor, cast iron table and wings, very accurate blade arbor alignment, 240 volt power, Great Fence and rail system and last but not least most aftermarket saw accessories fit without major modification. One example is the PSI saw Dust collection System and the other is The excellent Incra TS3 table saw and router fence system that delivers machine shop accuracy. This great saw has the great capability to have accuracy within one thousandth of an inch and can be a saw that lasts for years.

There is one thing I will let you know, the saw can be run with either 115 volts or 240 volts power. It is always easier on the motor, in this case a sealed motor that it run on the higher voltage. It will produce less heat and make a little more power with less amps at 240 volts. If you have never had to install a 240 volt socket in your workshop hire an electrician or have someone help you that knows how to do this task. It will help very little if you burn down your shop and house because you bought a new saw! You can even go to the home Depot and get a book on the subject and help from their staff but be sure you are positive that you know what your doing before installing that new power source.

Now do I put the black wire to ground or the white wire, from Johns tool crib,

Just kidding!