|

Obsolete Outboards |

|

| by

Max Wawrzyniak - St Louis, Missouri - USA

Bringing

a 1956 Johnson 15 hp Back to Life

Part

II: Water pump

Work |

|

Part

1 - Part 3 - Part

4 - Part 5 - Part

6 - Part

7

Before we get started on the water pump, I would

suggest a quick review of the old "Water

pumps" column, If Chuckie is going

to waste his bandwidth on that old stuff, we might

as well make good use of it.

For whatever reason, the two outboards featured in

the first two "Start to Finish" series were

about the most difficult of the old OMC (Outboard

Marine Corp., parent of Johnson, Evinrude, & Gale)

engines to change water pump impellers in. The 5 1/2

hp required that the whole powerhead be removed, while

the 25 required that one work through a small gap

between the lower unit and the exhaust housing ("tower"

housing") in order to disconnect the gearshift

linkage so that the lower units could be removed.

|

Exhaust

housing (AKA tower housing) and lower

unit overview

(click

images to enlarge) |

|

It is much easier to change the impeller in the '56

15 hp because this engine has a small access door

on the side of the exhaust housing which allows one

to disconnect the shift linkage easily. One loosens

the two screws and removes the little panel, revealing

a coupler connecting the shift rod coming-up from

the lower unit and the shift rod coming down from

the shift lever. The lower bolt of this coupler must

be completely removed, as the bolt engages a groove

in the lower portion of the shift shaft, and merely

loosening the bolt will not free the lower shaft.

If you drop the bolt down into the exhaust housing

at this point, it is no big deal, as the bolt will

fall out the bottom of the exhaust housing as the

lower unit is removed. If you accidently drop the

bolt when re-installing the lower unit, however, you

will have to remove the lower unit in order to retrieve

the bolt.

| Disconnecting

shaft coupler |

|

|

Once the shift shaft coupler is disconnected, the

five bolts holding the lower unit on can be loosened

and removed. Once these bolts are out, the lower unit

may fall-off the engine, or it might require a bit

of a tug if the shift shaft is hanging-up in the couple.

If the lower unit requires more than a minor tug to

free it, then something is not correct. It is a bad

idea to carry the lower unit around by the vertical

driveshaft; the shaft may slide out, dropping the

lower unit on your foot.

|

Wrenched

on lower unit mounting bolts |

|

Once off the engine, note if the copper water tube

came out with the lower unit or is still up in the

engine. This tube conducts water from the water pump

up to the powerhead, and if the tube is attached to

the water pump, pull it lose from the pump housing

and insert it up into it's hole up in the exhaust

housing. It is impossible to re-install the lower

unit with the tube attached to the pump; it must be

first inserted into the exhaust housing. When re-installing

the lower unit, you will need to guide that tube into

it's socket on the pump housing as the lower unit

is pushed up against the exhaust housing.

The tube is retained at both ends with "push"

fit rubber grommets and it would not be a bad idea

to replace these sealing grommets if there is any

doubt as to their condition. The one on the pump housing

is easy to pry-out and replace; the one up in the

exhaust housing is much more difficult. I decided

to risk reusing the old grommets on the 15.

| Water tube,

shift shaft and drive shaft details |

|

|

The top of the pump housing is held on with three

screws. One of these screws on the 15 came out with

some resistance and covered with white powder, which

was corroded aluminum. The long periods of submergence,

evidenced by the appearance of the lower unit, had

a detremental effect on the threads in the lower unit

casting. Fortunetly, only one threaded screw hole

showed signs of deterioration, and although it's threads

where in poor shape, there appeared to be enough thread

engagement to hold the pump housing on. Corroded or

stripped threads on these aluminum castings are a

farily common problem, and there where special tools

available to make drilling and re-tapping (re-threading)

water pump retaining holes a quick and easy job. Without

these special "jigs," the job is a bit more

difficult but not beyound the abilities of the careful

obsolete outboarder.

|

A special

jig (tool) for quickly repairing stripped

or broken water pump housing screws. Although

a more difficult job without the tool,

the basic procedures for repairs are still

the same. |

|

After the three screws are removed, the pump housing

can be slid up the driveshaft and removed. Note that

there is no gasket or seal used underneath the pump

housing. Also note that there appears to be no seal

for the driveshaft in the pump housing. Actually,

there is a "seal" of sorts for the driveshaft

where it passes through the pump housing. It is a

water seal; a cup which holds water acts as a shaft

seal. The water that keeps this cup full comes through

a tiny hole in the pump housing, and this tiny hole

must not be plugged. Excess water merely overflows

the cup and exits the motor through the exhaust outlet.

The pump impeller in the 15 was pretty much "toast."

The fins retained their "curved' shape, whereas

a good impeller will have "straight" fins.

My opinion is that once one has gone this far, it

would be dumb to reinstall the old impeller even if

it looked "OK." Unless I KNOW that the impeller

in an engine is good, I ALWAYS replace it. And I NEVER

re-install an old impeller once it is out of the engine.

| Impellers

and pump housing detail |

|

|

Underneath the impeller is a shiny metal "wear

plate." If this wear plate shows signs of heavy

scoring, if would not hurt to replace it. If the pump

housing itself shows signs of heavy scoring, replacing

that might be a good idea as well. So what constitutes

"heavy scoring?" Beats me. I have replaced

the wear plate in one or two of the engines that I

have worked on over the years; I can't remember ever

replacing a pump housing although I might have. A

pump "rebuild kit" will always have the

impeller and wear plate, and maybe the housing as

well. Or you can buy just the impeller and/or wear

plate seperately. I re-used the wear plate and housing

in the 15.

Water will sometimes do weird things. For example,

water will sometimes try to "climb" a spinning

shaft. for this reason, there is an "O"

ring in a groove around the splines at the top of

the vertical driveshaft. You will need to remove this

"O" ring in order to slide the pump housing

and pump impeller on and off the driveshaft. If the

"O" ring breaks, or if your engine is missing

the "O" ring, you might run the lower unit

by a good hardware store and see if they have an "O"

ring which fits pretty well. The fit is not real critical.

I will admit to occasionally not replacing a missing

"O" ring. The risk is allowing water to

get into the lower main bearing in the powerhead.

It can happen but doesn't always happen; your choice.

|

Are we

having fun yet? |

|

Slide the new impeller down the driveshaft and be

sure that the key way (notch) in the shaft hole of

the impeller engages the little pin on the driveshaft.

Slide the pump housing on the shaft. As you push the

pump housing down onto the impeller, rotate the driveshaft

in a clockwise (looking down) direction and the impeller

blades (fins) will bend back, allowing the housing

to drop down and seat on top of the wear plate. Make

sure that the impeller stays engaged on the drive

pin in the driveshaft. Install the three screws which

secure the housing. I was very carefull to not over-tighten

the one screw with bad threads. Replace the "O"

ring at the top of the drive shaft. A very light coating

of grease on the splines at the top of the driveshaft

is a good idea: any more than a VERY light coat is

NOT a good idea, as it can form a "hydraulic

lock", preventing the splines from fully engaging.

| Tools used

in changing the water pump impeller. |

|

|

Re-installing the lower unit might try your patience.

Take your time. Have the motor vertical if possible,

but high-enough off the ground so that you can get

the lower unit under it. You need to get the driveshaft

splines engaged with the splines in the crankshaft.

Having someone slowly turn the flywheel (clockwise)

might be of help. While doing this you also need to

guide the water tube into it's grommet on top of the

pump housing. Forget the shift shaft for the time

being. Once you have the driveshaft/crankshaft engaged

and the water tube in its grommet, install a few of

the lower unit mouinting bolts but leave them slack

so that the lower unit hangs with a little gap.

|

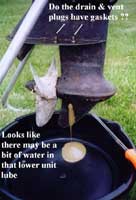

Looks

like there may be a bit of water in that

lower unit lube. |

|

Use needle nose plies inserted though the shift

shaft coupler door to move the lower end of the shift

shaft up and down, while using the shift lever on

the engine to move the upper half of the shift shaft

up and down, as necessary in order for the lower shift

shaft to engage the coupler on the upper shift shaft.

Be sure the lower shift shaft is fully seated in the

coupler and then re-install the lower bolt in the

coupler. Install and tighten-up all mounting bolts

and re-install the little cover over the access hole.

Check the shift lever while slowly turning the propeller

to see if the engine egages forward and reverse, and

that the prop turns freely in neutral. Remember that

either the prop or the flywheel must be turning when

trying to shift the engine or the engagement "lugs"

may not be aligned.

Removing the drain and vent plugs from the lower unit

released a "milk shake" looking mess that

indicated that there might be some water mixed-in

with the lower unit lube; taking my

own advice, I refilled the lower unit

with Lubriplate #105 white grease. I really did not

want to hassle with re-sealing this old, corroded

lower unit.

...

on to Part 3...

Happy Motor'n

click here for a

list of Columns by Max Wawrzyniak

|