I’m a high school student in South Korea. My school, Hyundai Senior High School, was established in 1985 by the late President Jung, the founder of Hyundai Motors Company. It is one of the best private schools in Seoul and we have a very special crew called “FETS” which stands for the expression, “From Earth to Sky.” It was created in 1992 and many machines, such as a man-powered-submarine and an eco-mileage-car, were made in the last twenty years. We also have several old FRP yachts. They are big enough to carry three or four students, but they are very hard to carry. Looking through Duckworks Magazine, some other students and I found out one person mini-yacht: Queen Mab and Stella.

I contacted the designer of Stella, Christer Bystrom, and thanks to his kindness, he sent me the plans for Stella. We chose the smallest one, Stella 73. We loved her easy-to-make side plank, tiny body, and computerized plan, but we wanted to make an offset centerboard in order to move our legs freely when in the water. Since I couldn’t make contact with Phil Bolger and Friends Inc. at that time - it was about August - we had to use only Queen Mab’s picture in Duckworks Magazine website.

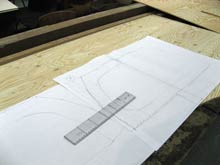

We bought two sheets of 2400*1200*4mm plywood and one sheet of 2400*1200*7.5mm-plywood. At first, we made the body just as the plan said. It was very hard to back the backbone straight and attaching the planks without making big space between them was also not easy.

Later, a much more important operation emerged. We had to match Queen Mab’s centerboard case to HD24’s body. While looking at the pictures, we made a hole at the bottom of the right side. Fortunately we were able to put the centerboard case from Stella’s plan into the right side without any modification. We fastened it with screws initially, and filled the gaps with epoxy to prevent water coming in.

The centerboard was just like a simple wooden plate. We cut the thick plywood into shape and just spread varnish on it. We put fiber-glass on all sides of the body to strengthen and waterproof it, but later we found out that this work had made her much heavier.

For the mast, we used some pine timber which had been in our garage for twenty years. We put three pieces together and glued them with epoxy. The combination of the three parts was way stronger and it was less likely to be bent. The gaff and boom were made in a similar way.

Our HD24 looked almost finished, even in this early stage, but much more hard work was waiting for us.

Actually, yacht sailing isn’t a very popular hobby here in Korea and the term “yacht” is often considered as the expensive motor yacht and a symbol of extravagancy. Thus, there are few yacht builders here. That’s why our project was very meaningful: the project of building Korea’s first one-person-sailing yacht.

Next, we had to mount the rudder. It was made long before with Larch plywood from Brazil (referred as 2400*1200*7.5mm-plywood above). What we had to do is to attach the rudder to the body of HD24. It wasn’t that easy. We bent the stainless steel to an Ω(omega) shape and made the opposite part in a T shape by welding two pieces. We really wanted to buy factory-made parts, but there was no choice because of the lack of demand and supply of yacht parts in the Korean market. The shape wasn’t perfect, but we were happy to see the rudder working well after it was attached.

Meanwhile, we approximated the size of the sail using only the boom, gaff, mast and a friends’ hands. With that approximate measurement, I went to the biggest textile market in Seoul: Dong-dae-mun market which is located at the east gate of medieval Seoul. I told the seller the size of the sail and I chose the material with which he would make the sail. When the tailoring was finished I brought it to the school to check and see if it fit. Since the size given to the tailor was calculated just by approximate measurement, we found a few wrong sections. We marked those sections and I took it back to the textile store. After that, the sail was quite perfect.

All parts being done, we brought HD24 to the Han River and had an experimental sail. She sailed quite well but we found one small hole which allowed water to come in. We reinforced that part and she was finally done.

We had a celebrating party with principal and vice principal of our school on October 19th, 2011. It was really festive and all students were really fascinated to see the sailboat made by their fellow students. Still not satisfied, the ambitious members of FETS are planning a second project.

|